Solar Panel Cleaning Robotics

Carla Dawson

September 23, 2022

Ask the right questions before deciding what solar panel cleaning robot to buy.

As solar panel cleaners race to buy their first robot, they often overlook what an important decision this is. These guidelines were created for cleaners who are shopping for a solar panel cleaning robot.

Important Parameters

- Does the robot have edge detection technology and how many sensors does the robot have?

- How many configurations does the robot have?

- What surface area does each configuration cover?

- Does the solar panel cleaning robot manufacturer have a local distributor?

- How long is the warranty?

- What is the heaviest piece and is it under 50 pounds (OSHA guidelines)?

- How can you transport the machine? This is very important. Solar panels are in hard-to-access areas?

- Can the machine be easily repaired and does the manufacturer offer videos that show you how to repair it?

- Can the machine be picked up and flowing with an aerial lift to get it onto a rooftop?

- How abrasive are the brushes and have they been tested? Abrasive brushes damage the panels are remove the valuable antireflective coating.

- Does the machine have electroluminescent testing?

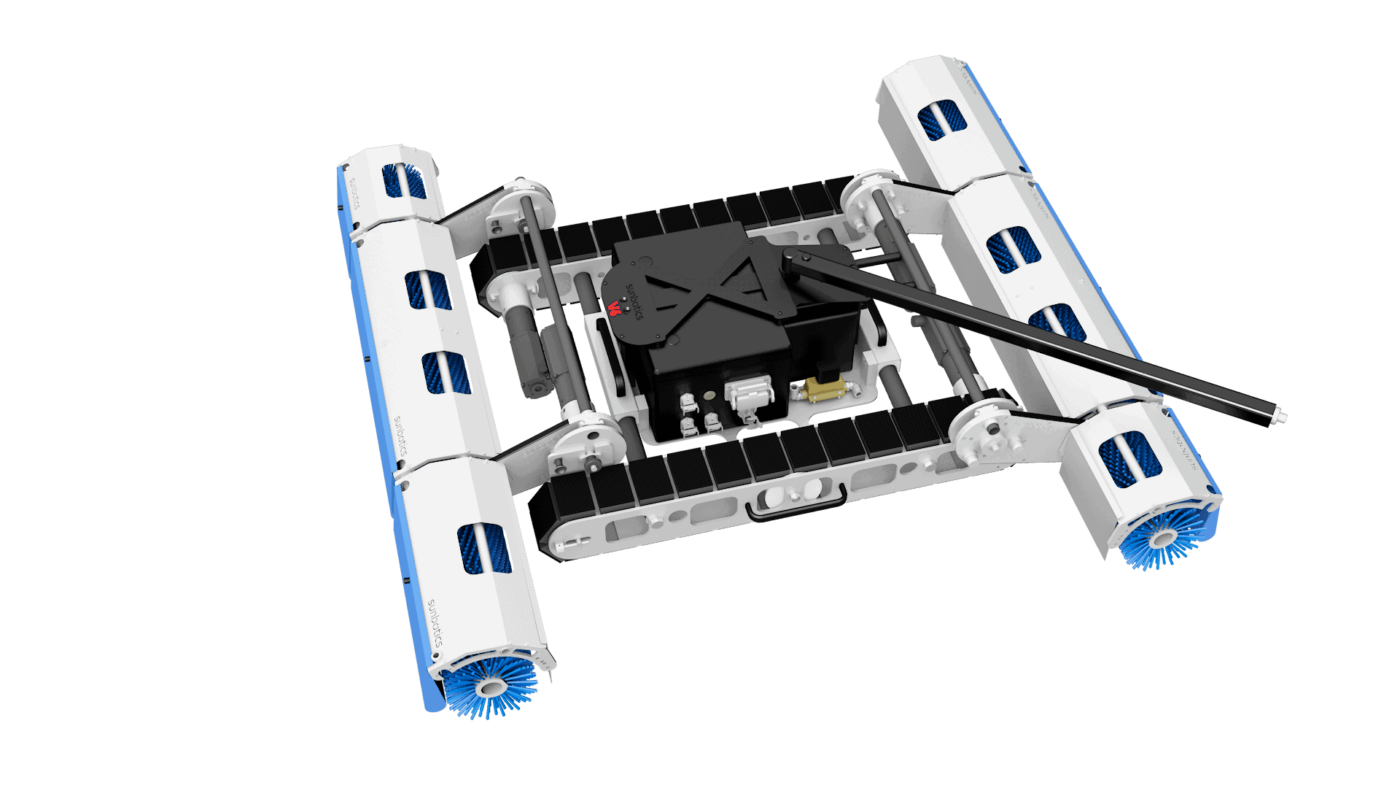

- Does the manufacturer show you up close pictures of the parts? Part quality is very important.

- What is the total weight of the robot?

- What is the contact pressure on the solar panels?

- What is the maximum inclination that the robot can be used without a safety guidance tool?

- What is the maximum inclination with a safety glider?

- What is the water consumption rate?

- What is the max gap the robot can cross on a flat surface?

- What is the max gap the robot can cross on an inclined surface?

- Does it have a cruise control function?

- Where is the robot manufactured?

- What are common repairs that are needed and how are they done?

- Can I buy your parts locally?

One of the biggest issues in the industry is that manufacturers often stretch the truth and what they say is not necessarily what they deliver. Asking a client of theirs doesn’t solve this problem because almost all manufacturers have an affiliate marketing program with their clients.

We highly recommend testing the robot in a real demo to get a better understanding of what you are buying. The industry is not regulated in any way and it is the wild west out there.

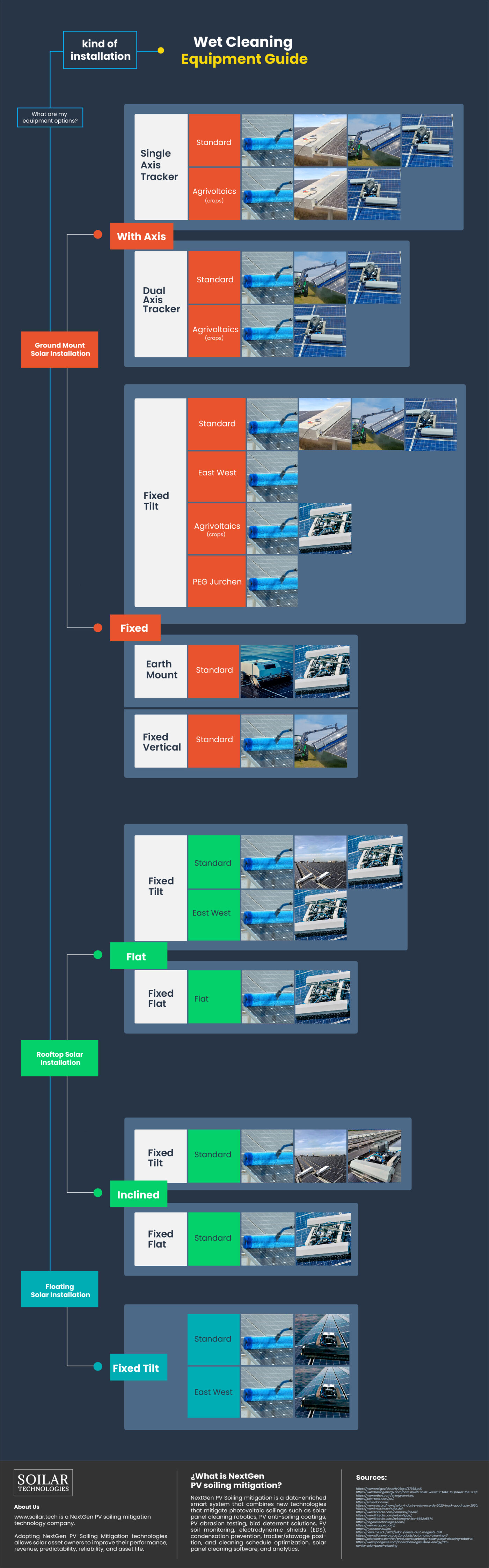

We also recommend understanding how your robot can be used on each one of these installation types and what accessibility issues are encountered.

Are most solar panel cleaning robotic systems cobot systems?

Yes, they are….so what is a cobot solar panel cleaning system?

What is a cobot?

Cobots are the latest technology in robotics and have changed the world of automation significantly. The name cobot is a derivative of “collaborative robot”. These robots are collaborative because they can safely work together with people. They can do this because they are equipped with sensitive sensors that give the robot a “feel”. If the robot is interrupted in its work, it will shoot into a safety mode. Traditional robots would simply continue their way, potentially injuring people.

Here are some important statistics to take into account when deciding what robot to purchase

- Less than 1% of installations are floating in the USA. Floating installations will grow but at a very small rate in the USA due to the fact that land is cheap and abundant. Floating installations are successful in places where land is expensive and scarce such as the Netherlands, Japan, etc.

- Commercial solar installations are estimated to grow at 8% annually in the USA or more. The passing of the IRA and other local legislation is catapulting commercial solar installation growth. Large companies like Amazon, Target, Walmart, etc have all made NetZero pledges. Large rooftop solar installations create 90% of the energy they consume.

- 1.1 Billion solar panels will be going up in the USA in the next 8 years just for the commercial, industrial and utility-scale segments.

- Cleaning frequency varies across the USA but the minimum is 1 cleaning per year. In places like the southwest, it makes sense to clean 3 – 12 times a year.

- Solar Panel Cleaning improves performance, reliability, asset life, and compliance

Overview of Solar Panel Cleaning Equipment Nomenclature

Because the solar panel cleaning equipment industry is so young, the nomenclature varies significantly. Different people have different definitions of the term “solar panel cleaning robot”. The term robot implies “full automation”. Some important facts to know to understand the categories within solar panel cleaning equipment. Dry Cleaning should only be done in areas where humidity levels are nonexistent. Dry cleaning solar panel cleaning equipment can be fully automated through a system called a fixed slider or the PV Dry Rumba. Wet cleaning equipment has not been fully automated to date and you will not find a cost-effective wet cleaning system that is fully automated in the marketplace. The application of dry cleaning systems in areas where there is humidity increases PV abrasion levels. Humidity causes the cementation of soiling particles on solar panels.

Wet Cleaning Solar Panel Cleaning Equipment Nomenclature

Since the majority of the world will have to use wet cleaning systems, it is important to understand the main buckets

Residential Solar Panel Cleaning Equipment

- Water-Fed Pole – Manual Systems

- Powered water-fed pole – Semi-Automated Systems

Commercial Solar Panel Cleaning Equipment

- A powered water-fed pole also known as a rotary brush

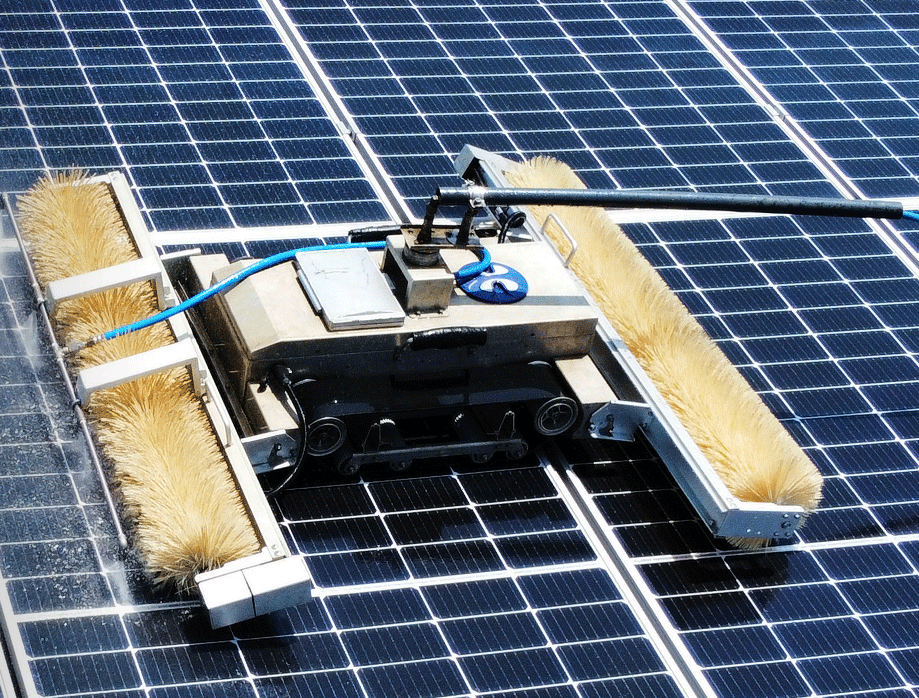

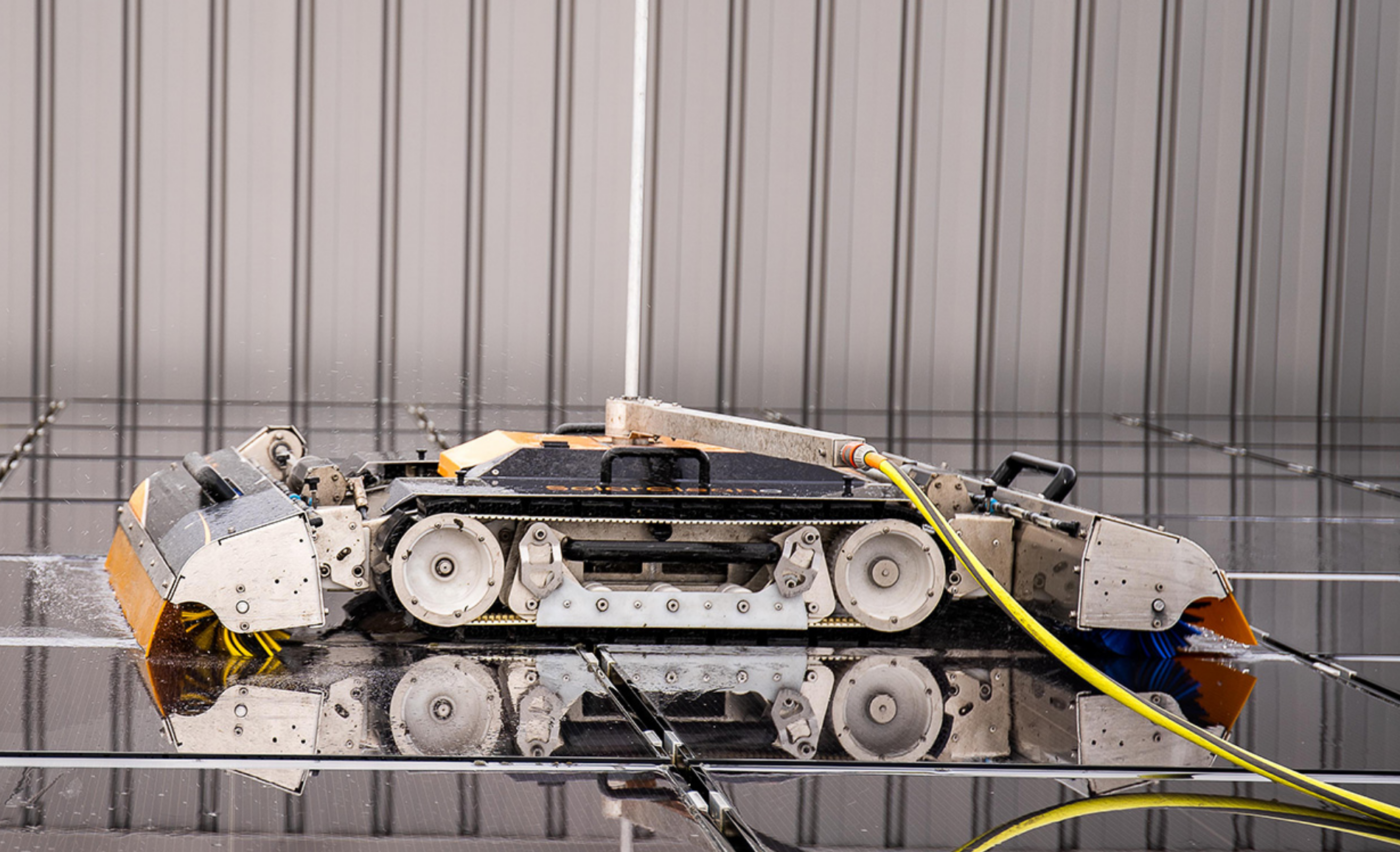

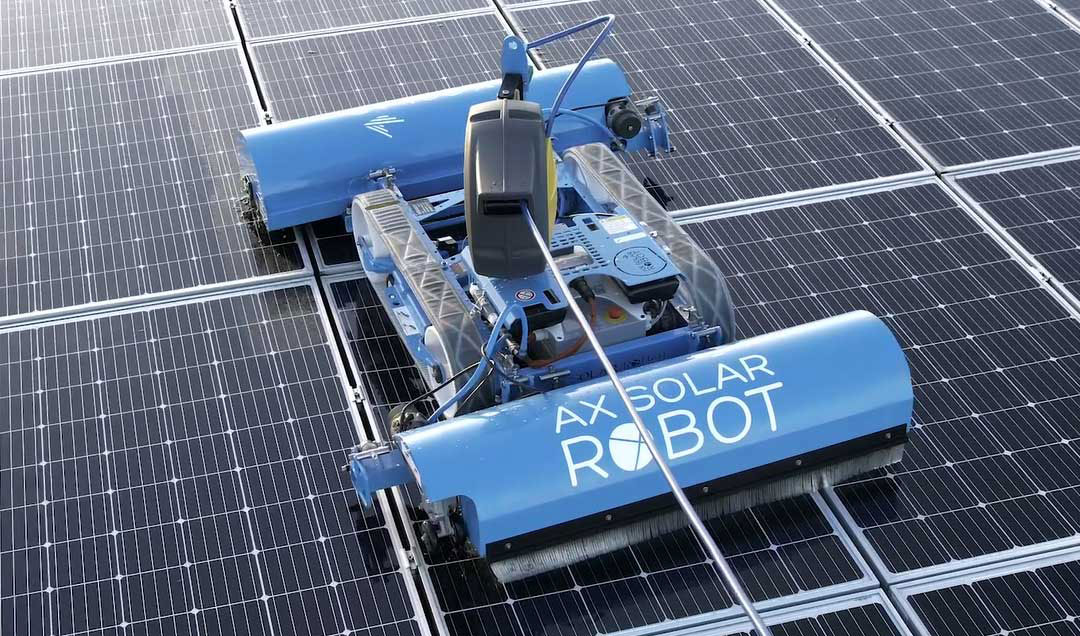

- Solar panel Cleaning robots – Semi-Automated systems

Utility-Scale Solar Panel Cleaning Equipment

- A powered water-fed pole also known as a rotary brush

- Solar panel Cleaning robots – Semi-Automated systems

- Tractor-Brush Systems

- Powered Lift and Shift Systems

- Innovations in progress.

- Here is an example of a completely automated dry cleaning machine.

Innovation

Solar panel cleaning robotics is an innovative segment and a young segment. The oldest solar panel cleaning equipment company is 7 years old. While the industry matures, it will evolve and get better with time.

If you are interested in learning about solar panel cleaning robotics, please reach out to us.

Follow us on Instagram, Linkedin, Twitter.

Copyright © 2019 Carla Dawson. All rights reserved.

All documents are protected within the meaning of copyright law.

Carla Dawson reserves all rights to exercise intellectual property rights.

Copying of this content is not permitted without express written authority.

Violations are an offense and are liable for damages.

About the author

Carla Dawson founded Soilar Technologies, a NextGen PV Soiling Mitigation Technology Company in 2019.

NextGen PV soiling mitigation can be defined as:

“Mitigating photovoltaic soiling by using 21st-century technologies throughout the solar plant lifecycle with the objective of increasing performance, reliability, asset life, and warranty compliance. NextGen PV Soiling mitigation is typically a data-enriched smart system that combines technologies such as solar panel cleaning robotics, PV anti-soiling coatings, PV abrasion testing, bird deterrent solutions, PV soil monitoring, electrodynamic shields (EDS), condensation prevention, tracker/stowage position, and cleaning schedule optimization, solar panel cleaning software, analytics and other technologies.”

NextGen PV soiling mitigation is a phrase that was coined by Carla Dawson and Klemens Ilse in 2022.

Soilar Technologies is dedicated to helping solar panel cleaners, EPC, solar installation companies, and entrepreneurs solve their PV soiling problems from design to the operations and maintenance stage.