Solar Farm Cleaning Costs

Carla Dawson

August 31, 2022Solar Farm cleaning costs vary by country, region, and the state of each solar farm. Solar farms in good condition with water onsite and close to urban areas can be cleaned at approximately the following rates.

If you want a Solar Farm Cleaning Company, please check out our Partners page. We provide solar panel cleaning suppliers worldwide. https://soilar.tech/partners/. If you are interested in learning more about the Solar Farm Cleaning business, please enroll in our NABCEP-accredited online school here Solar Panel & PV surface cleaning school. If you are interested in our solar farm quoting spreadsheet, then you can download it here. Professional solar panel cleaning equipment can be found here.

Please keep in mind that these numbers are just a reference and local issues will change what a solar panel cleaning company will charge you. These numbers also vary if the client requires lots of credentials and conditions which is often true with government contracts. The solar farm cleaning industry typically goes by “price per panel” & mobilization and demobilization fees. We highly recommend that the industry consider square footage or square meters as a better way to bid on projects since panel sizes vary significantly in size.

| Utility Scale | Price per Panel (Standard Panels) I highly recommend charging by Square footage or similar |

| 10 MW | $0.75 – $4 + mobilization & demobilization fees |

| 11 – 50 MW | $0.65 – $1.25 + mobilization & demobilization fees |

| 51 – 100 MW | $0.55 – $1 + mobilization & demobilization fees |

| 101 MW – 250 MW | $0.37 – $0.75 + mobilization & demobilization fees |

| Commercial & Industrial | |

| Carports (1 MW) | $1.50 – 10 + mobilization & demobilization fees |

| Rooftops less than 1 MW but not residential | $2.00 – 10 + mobilization & demobilization fees |

| Rooftops more than 1 MW | $1.50 – 10 + mobilization & demobilization fees |

Most solar farm cleaning bids in the US have few specifications and requirements. We highly recommend that solar farm cleaning services and bids include these concepts.

- Cleaning with Deionized Water or less than 10 PPM

- Cleaning Systems must have abrasion testing certifications or PV module manufacturer certifications.

- Clean during the daytime since cleaning at night has significant safety risks.

- Require solar panel cleaning safety measures

- Safety protocols to reduce the risk of electrocution

- Time to clean the site

- Onsite inspection to participate in the bid – For existing PV sites, we recommend that the asset owner require that the solar panel cleaning company visit the site to be able to participate in the bid to increase project success.

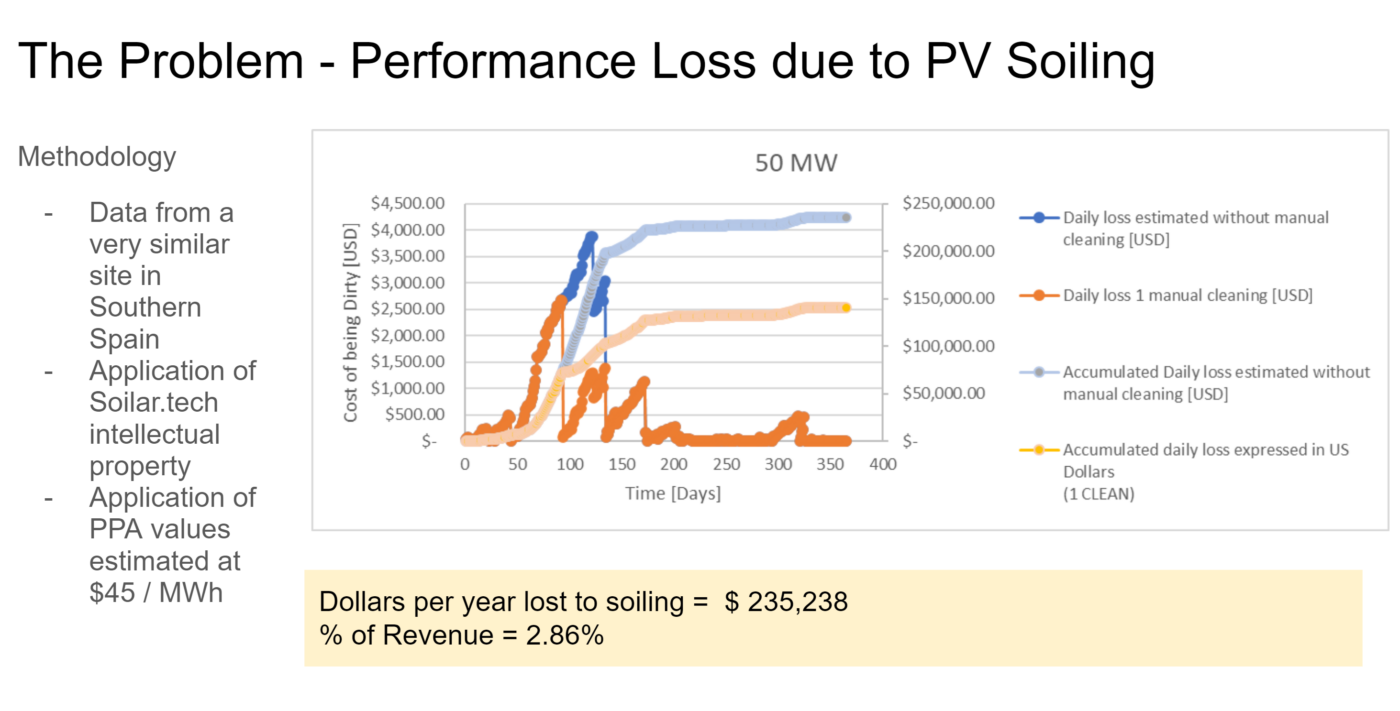

Case Study – 50 MW at $45/MWh

The economics of performance loss and PV soiling and solar panel cleaning can be measured and that is what we do at Soilar Technologies. The following case study is about a solar farm with 50 MW of installed power at $45/MWh.

The Challenge – 50 MW

- Quantifying the revenue loss due to soiling

- Quantifying the ideal cleaning frequency and schedule

- Quantify the value add from solar panel cleaning

- Defining the solar panel cleaning equipment that allows for maximum efficiency for the existing PV design

- Altering the PV design to allow for

- Efficiency

- Operator Safety

- Identification of key difficulties in cleaning the solar installation

- Opportunity identification

We highly recommend determining the cleaning schedule by using our PV Soiling Monitor and software.

CASE STUDY – 100 MW at $28/MWh

Determining the cost of cleaning a utility-scale solar installation is best done by analyzing the entire system vs the cost of just the machinery. Each installation is unique and we have chosen to use a case study to help you understand the costs related to solar panel cleaning solutions.

Our case study covers a solar farm in Southern California with PPA values of USD $28/MWh and average daily soiling levels at 0.08%. By applying soiling monitoring and semi-automated cleaning systems, the solar plant achieves savings of 3.6 Million Dollars over the lifetime of the solar installation. Below you can see what options are available to clean a solar farm and their associated costs.

Solar Farm Characteristics

- 100 MW

- Region – Southeast CA, USA

- USD $28 / MWh

- Soiling Monitoring – DustIQ by Ott HydroMet

- Annual Soiling Cost = USD $272,000

- Labor Rates = $35/hr

Solar Panel Cleaning Costs

The financials above cover 10 years of a utility-scale installation the CapEx is prorated over these 10 years.

The cost of cleaning a solar farm is a function of the cost due to soiling and the cost to clean a solar farm. In the case study, you can see that in year one it makes sense not to clean manually but it does make sense to clean with semi-automated solutions.

We analyzed just 3 solar panel cleaning systems and compared the cost of soiling and cleaning to the estimated revenue of the solar farm.

As you can see in the financials above, the cost of soiling and cleaning is a significant part of revenue. In the case study above, if we do not clean, soiling amounts to 2.9% of our revenue, while if we clean in an optimized way, we can reduce this cost to 1.6% of our revenue. Most solar farms have linear revenue and fixed PPA’s so the opportunity to improve earnings over the lifetime of the solar installation is done by reducing O&M costs.

Solar panel cleaning costs should be determined by looking at the cost of the system and not just the machinery or the robotics. Solar panel cleaning systems have a CapEx and OpEx and each installation will require its own unique analysis because

- PV Soiling rates and distributions are unique to each site

- Optimum solar panel cleaning machinery and or robots are unique to each site

- Studying the financials is key

- The cost of water should be contemplated

- The cost of labor should be contemplated.

- When you clean is extremely important and one of the most important variables. Below we established a 5% soiling rate threshold to determine when to clean and compare the cost of being dirty to the cost of each cleaning from an operational point of view.

Conclusion

Reach out to us for a free initial consultation.

Solar panel cleaning costs on commercial, industrial, and utility-scale installations require

- Localized considerations and financial analysis by people specialized in this topic.

- PV Soiling Monitoring to determine how big the problem is and when the problem occurs (soiling distribution values)

- Solar panel cleaning engineering – Each solar panel cleaning system has its own pros and cons. It is important to work with a team of people experienced in this field.

If you are interested in cleaning your PV site optimally please feel free to reach out to us at Soilar.tech. We offer solar panel cleaning system design engineering services and we also sell robotics to help clean more efficiently.

Follow us on Instagram, Linkedin, Twitter.

Copyright © 2019 Carla Dawson. All rights reserved.

All documents are protected within the meaning of copyright law.

Carla Dawson reserves all rights to exercise intellectual property rights.

Copying of this content is not permitted without express written authority.

Violations are an offense and are liable for damages.

About the author

Carla Dawson founded Soilar Technologies, a NextGen PV Soiling Mitigation Technology Company in 2019.

NextGen PV soiling mitigation can be defined as:

“Mitigating photovoltaic soiling by using 21st-century technologies throughout the solar plant lifecycle with the objective of increasing performance, reliability, asset life, and warranty compliance. NextGen PV Soiling mitigation is typically a data-enriched smart system that combines technologies such as solar panel cleaning robotics, PV anti-soiling coatings, PV abrasion testing, bird deterrent solutions, PV soil monitoring, electrodynamic shields (EDS), condensation prevention, tracker/stowage position, and cleaning schedule optimization, solar panel cleaning software, analytics and other technologies.”

NextGen PV soiling mitigation is a phrase that was coined by Carla Dawson and Klemens Ilse in 2022.

Soilar Technologies is dedicated to helping solar panel cleaners, EPC, solar installation companies, and entrepreneurs solve their PV soiling problems from design to the operations and maintenance stage.